Ford Using Bubbly Plastic to Save Weight, Fuel

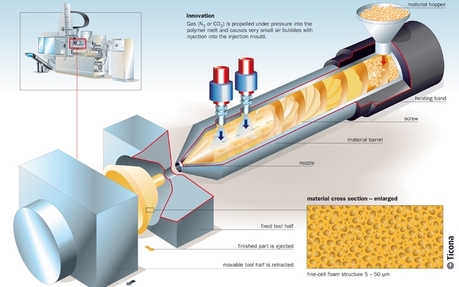

In an effort to decrease their vehicles’ curb weight and subsequently reduce fuel consumption, Ford has turned their attention to a new plastic technology coming out of MIT. Called MuCell, the new plastic material is handled much like most other plastics, but is treated to a nitrogen infusion during the injection molding process. This creates tiny bubbles measured in micrometers within the plastic, reducing weight significantly while only slightly reducing strength. Ford hopes to use the material in interior and underhood plastics in an effort to reach their weight reduction goals of 200 to 750 pounds, but don’t expect to see any until 2020.