Jaguar Land Rover’s Manufacturing Breakthrough Could Net Major CO2 Savings

Modern vehicles are increasingly fuel-efficient and clean, but there’s still a lot of room left for improvement. And this is true even for electric cars that will transform the automotive landscape in years to come.

As you know, their environmental footprint can’t be measured just by tailpipe emissions. We must also tackle pollution at the source, meaning from the extraction of raw materials to vehicle manufacturing at the plant.

- Also: Contactless Touchscreens Are the Future, Jaguar Land Rover Says

- Also: 2021 Jaguar I-PACE: New Infotainment and Faster Charging

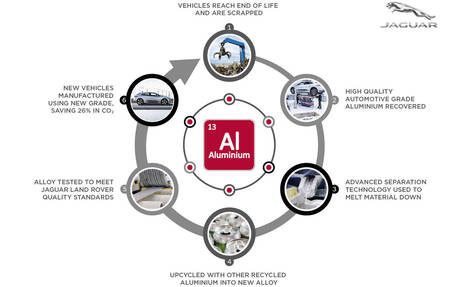

A number of solutions have already been implemented or soon will be. Jaguar Land Rover, for example, is currently testing an innovative new process for using aluminum waste from old vehicles and household appliances into new production vehicles.

Engineers have found a way to blend the recycled aluminum with a lower amount of primary aluminum to form a new prototype alloy that meets the manufacturing quality standards of Jaguar Land Rover. A pre-production Jaguar I-PACE prototype is being used for testing purposes.

According to research conducted in partnership with Brunel University in London, Jaguar Land Rover estimates this could ultimately reduce production carbon emissions by up to 26 percent.

The Aluminium Association (a global trade association for the aluminum production, fabrication and recycling industries and their suppliers) calculates that recycled aluminum uses around 90 percent less energy than raw material production.

Post-consumer recycled aluminum is used in drinks cans, aerosols, foil food trays, plates and bottle tops, among other things, but is marginally used in automotive manufacturing. Breakthroughs like Jaguar Land Rover’s are promising indeed.